Atomic force microscopy

Atomic force microscopy (AFM) is a powerful technique that enables the imaging of almost any type of surface, including polymers, ceramics, composites, glass, and biological samples. AFM is used to measure and localize many different forces, including adhesion strength, magnetic forces, and mechanical properties. AFM consists of a sharp tip that is approximately 10 to 20 nm in diameter, which is attached to a cantilever. The response of the cantilever when interacting with a surface encodes different properties of the surface and this response is inherently non-linear. Multifrequency lock-in amplifier MLA-3 and the Multifrequency AFM kit can measure up to 32 harmonics of the non-linear response of the cantilever, enabling you to extract properties of the surface faster and with better sensitivity.

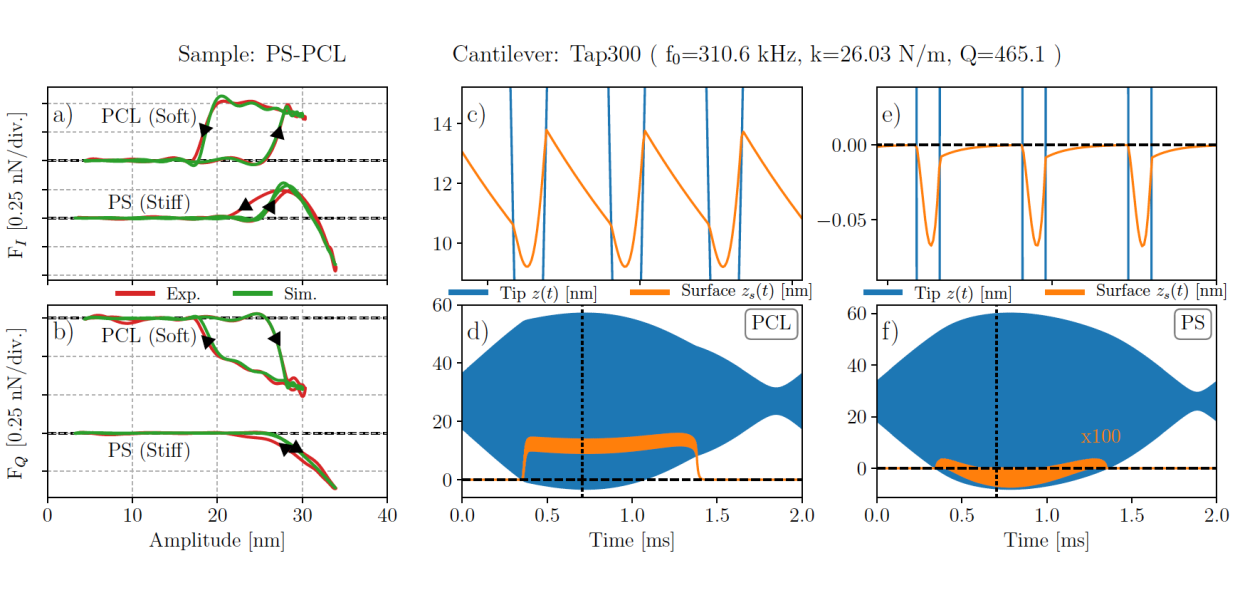

Solution: Using the Multifrequency AFM kit and a moving surface model one can extract the characteristic time constants for tip penetration in to the surface, and relaxation of the free surface.

User: Per-Anders Thorén, PhD student at KTH, Sweden

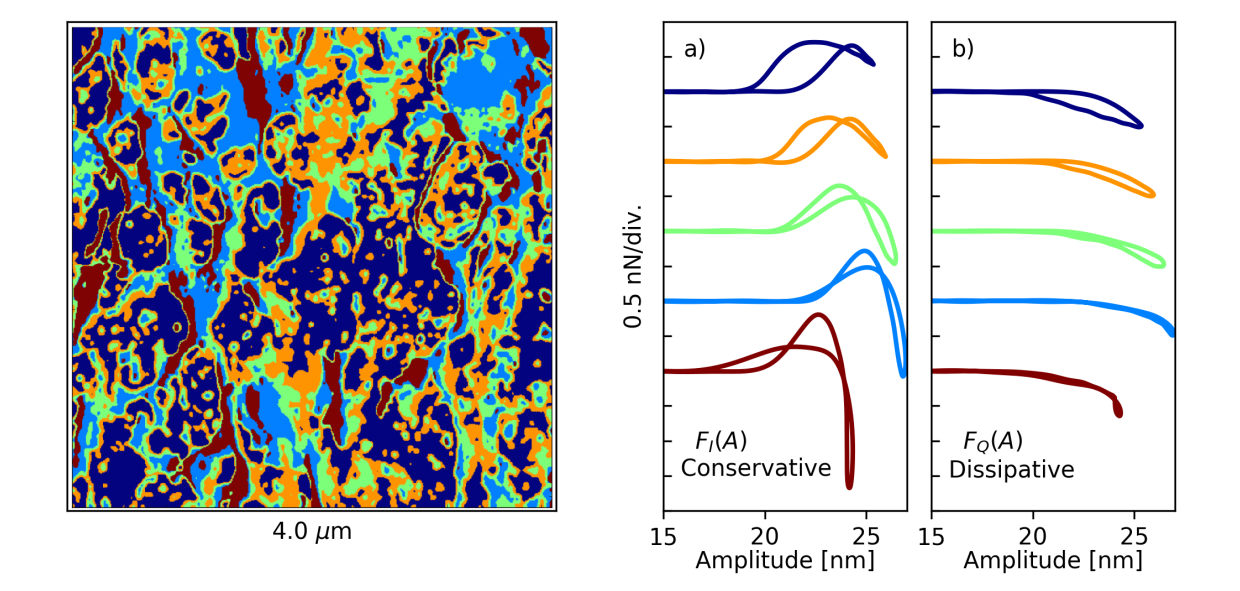

Solution: Machine learning attempts to group or cluster the pixels in this space. The ImAFM Software Suite comes with functionality for k-means clustering. Other clustering algorithms are easily programmed using the scripting interface and the Python module scikit-learn.

User: Hailu G. Kassa, University of Mons - UMONS, Belgium